New in Integrator V7.2. Tags are used to communicate information between the PLC and Sym3. Tags are associated with one type and can return Value and Quality for the Tag.

Tag names must be unique, cannot contain any space characters. The math symbols (-/*+) must be avoided so that these are not evaluated as part of an expression.

New Tags can be created in Sym3 using the Tags Manager that can be accessed from Ribbon > Home > Tags

Clicking on + creates a new Tag with a default name (Tag1) in the Tag Manager Panel. Double-click on this name to change it. This name has to be unique in this list.

Pressing this button prompts the user that they will be deleting all Tags. A Yes response removes all Tags from the list. This is most often used to clear all Tags before a re-import to update changes.

Open the Tag Manager, select the few tags and you can change the property of Tags all the selected Tags in one go.

Opens a file open window that should be browsed to a suitable CSV Tag import file. If any inconsistencies or errors are encountered then these appear in a window and no Tags are imported.

Opens a file open window that should be browsed to a suitable location to save the CSV Tag export file. You can export invalid or faulty Tags.

Opens an OPC Tag Browser window on the Data Source to allow adding these to the Tag database. The list shows Tag Name, Type and Detail.

This button turns on the polling of all the tags reading the value and quality, displaying it in the rightmost columns.

This option is used to verify the connection to the Data Source is working.

The Search field offers a filter such that only Tags matching the filter are displayed in the list. To see all Tags, ensure this field is empty.

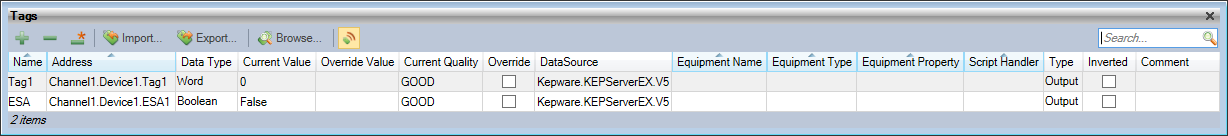

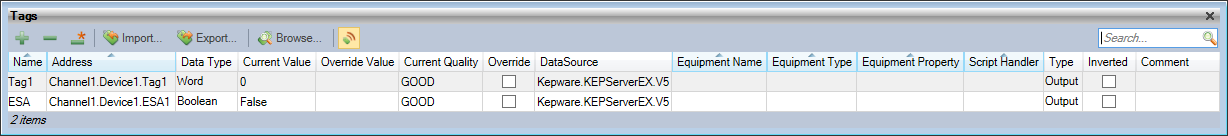

In this example the ESA tag is 'GOOD' and has a current value of 'False', Tag1 has a value of zero.

In the Tag Manager,right click on a tag,a contextual menu pops-up with one action "Locate Equipment". Using this action on a valid equipment,will locate equipment in 3D view and display properties.Same is the case for Device I/O.

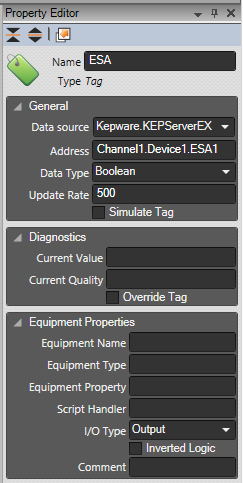

The property settings for the selected Tag will appear in the Property Editor Window and allow changes to its properties;

Name: Unique name of the Tag

General:

Data source: The data source to read the values from

Address: PLC address for the Tag

Data Type: Select from one of the following supported data types;

Default: Defaults to Short

Boolean: Boolean (0 or 1)

Char:

Byte: Byte (0 - 255)

Short: Int 16 (-32767 - 32767)

Word: Unsigned Int 16 (0 - 65535)

Long: Int 32 (-2,147,483,647 - 2,147,483,647)

DWord: Unsigned Int 32 (0 - 4,294,967,295)

Float: Float

Double: Double

String: String

Date:

Update Rate: Update interval in milliseconds e.g. 500 = 0.5 secondsSimulate Tag: Defaults to unticked but tick to simulate the Tag (no PLC used)

Diagnostics:

Current Value: The current value for the Tag when Show Live Values has been used

Current Quality: The current quality for the Tag when Show Live Values has been used. A zero indicates a Good (reliable) quality while any other value indicates potential uncertainty in the value it returns. See " OPC Functions" for quality values.

Override Tag: Force the tag value to what is entered in the Value

Equipment Properties:

Equipment Name: The name of the equipment in the Project Explorer

Equipment Type: The type of equipment e.g. Conveyor, PE Sensor

Equipment Property: The property being changed e.g. Running, Blocked

New in Integrator V8.0. When it is necessary to send to Datasource (so for Output Tags)a 32bit value (for example: Encoder value) while the Datasource supports only WORDS (16bit). It is possible to extract the lower word and the higher word using LOW(xxxxx) and HIGH(xxxxx).Example:

Script Handler: Script to execute for complex data conversions

The Equipment Property script handler has the signature void xxxxxx(Object equipment, String identifier, Object value, Number quality)

The function that is to be invoked when a tag state change occurs

| Name | Type | Description |

| equipment | Object | The Equipment Object associated with the Tag |

| identifier | String | The Equipment Property or an user supplied identifier string |

| value | Object | The new value of the tag |

| quality | Number | The quality value associated with the tag update. See below table for quality values |

I/O Type: Input (data into Sym3) or Output (data from Sym3)

Inverted Logic: Invert Boolean type only (True to False, False to True)

Comment: User comment for Tag

The Tags file for both Export and Import will have a CSV structure similar to;

TagName,DataSource,Address,DataType,RefreshRate,Simulate Tag,EquipmentName,EquipmentType,EquipmentProperty,ScriptHandler,IOType,InvertedLogic,Comment Tag1,Kepware.KEPServerEX.V5,Channel1.Device1.Tag1,Word,500,0,,,,,Output,0, ESA,Kepware.KEPServerEX.V5,Channel1.Device1.ESA1,Boolean,500,0,,,,,Output,0,

New to Integrator V7.2

Tags allows information for multiple equipment to be exchanged as a single message to a PLC. The Tags translate the equipment property to bit(s) in the message. The PLC program interprets the message and processes the information as required.

To aid the PLC Engineer in testing the PLC and Sym3Integrator projects, the current value and an override button has been added.

For convenience and consistency with the Tags, two new columns have been added to the Tag manager.

| Column | Description |

| Override Value | The override value supplied by the user |

| Override | Boolean, default false. Flags if this value is to be overridden |